Why Should The Globe Valve Enter From Low And Exit From High?

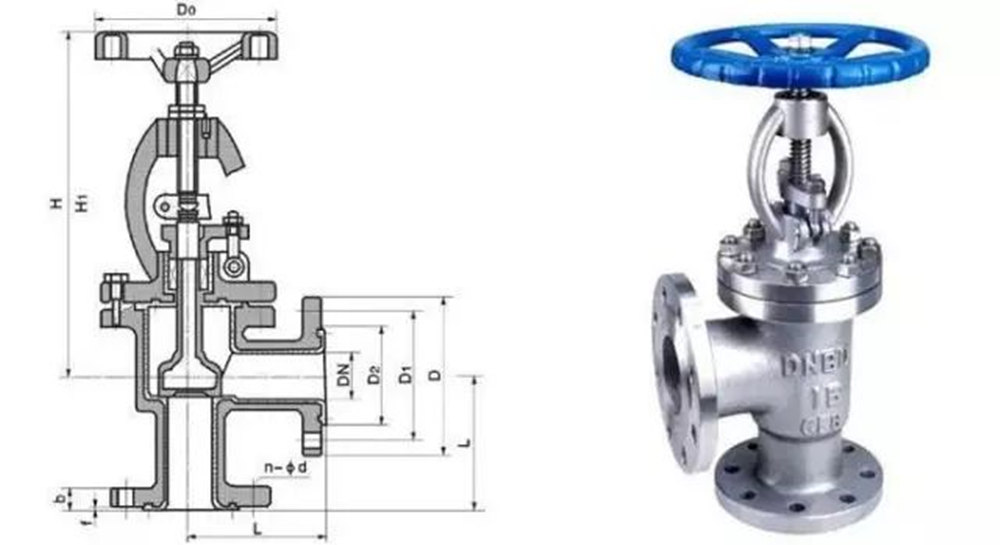

The globe valve,belongs to the forced sealing valve, which is a kind of cut-off valve. According to the connection mode is divided into three kinds: flange connection, thread connection, welding connection.

The flow direction of the stop valve is always from top to bottom, so the installation is directional.

This type of cut-off valve is very suitable for cutting or regulating and throttling. Because this kind of valve stem opening or closing stroke is relatively short, and has a very reliable cutting function, and because the change of the valve seat opening is proportional to the stroke of the valve disc, it is very suitable for flow regulation.

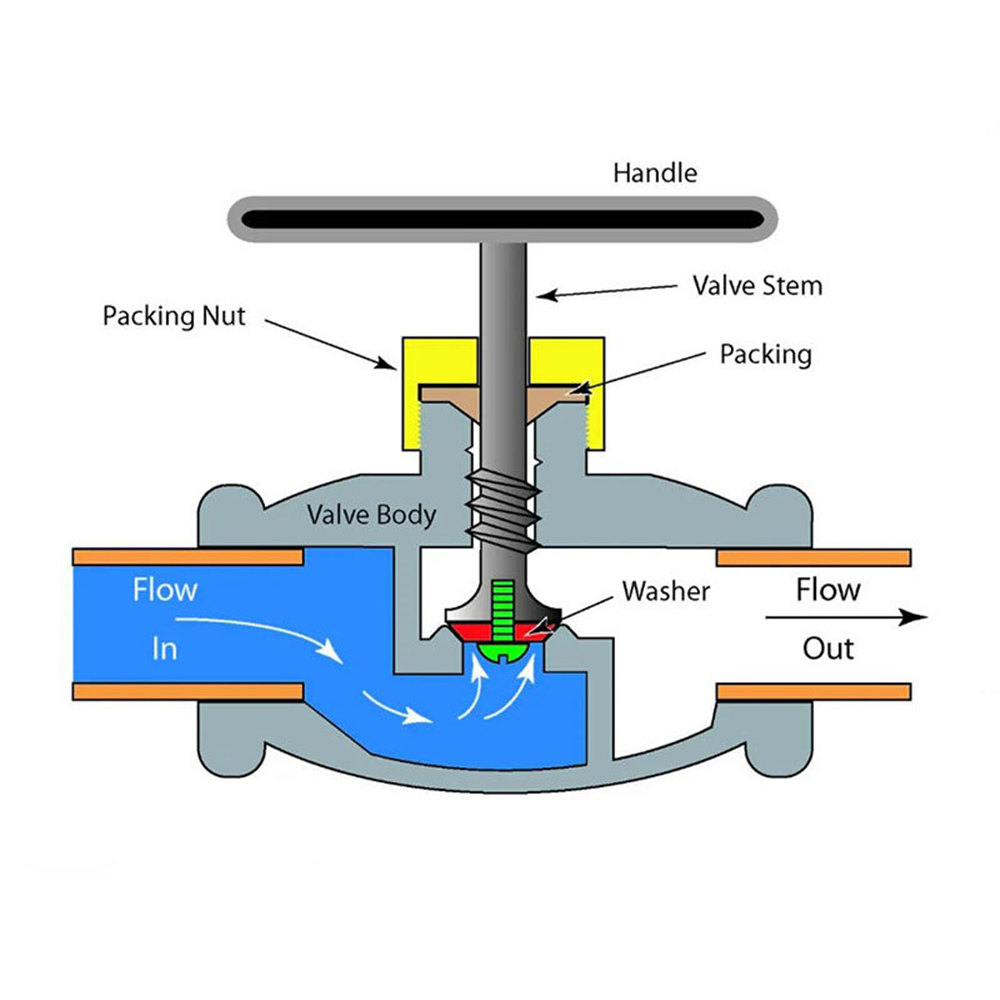

The globe valve is designed to enter from low and exit from high in order to make the flow resistance small and save labor when opening the valve. At the same time, when the valve is closed, the packing material between the valve shell and the valve cover and the packing around the valve stem are not stressed, and the medium pressure and temperature are not affected for a long time, which can prolong the service life and reduce the probability of leakage. In addition, the packing can be replaced or added when the valve is closed for easy maintenance.

But there are also some special cases of the globe valve is entering from high and exiting from low:

1.High pressure stop valve with diameter greater than 100mm

Due to the poor sealing performance of large diameter valves, using this method, the medium pressure acts on the top of the valve disc in the closed state to increase the sealing performance of the valve.

2.Two shut-off valves are connected in series on the bypass pipeline. The second shut-off valve requires ' high inlet and low outlet '.

In order to ensure the tightness of the valve in a maintenance cycle, the valve that is often opened and closed requires two series stop valves. For the bypass system, the installation of this bypass has the following functions : ①Balance the pressure before and after the main pipeline valve, so that the opening is convenient and labor-saving, and reduce the wear of the main pipeline valve ; ②Small flow warm pipe during start-up ; ③On the main feed water pipeline, control the feed water flow to control the boiler pressure rise speed for boiler hydraulic test. According to the direction of medium flow, the bypass cut-off valves are primary valve and secondary valve respectively. When the unit is in normal operation, the primary valve and secondary valve are closed, both of which are in direct contact with the medium. In order to prevent the padding between the secondary valve shell and the valve cover and the packing around the valve stem from being affected by the medium and temperature for a long time, and the packing of the valve can be replaced during operation, the installation direction required by the secondary valve is ' high in and low out '.

3.Boiler exhaust, vent stop valve

The exhaust and venting cut-off valves of boiler are only used in the process of boiler start-up and water supply. The frequency of opening and closing is small, but the working fluid loss is often caused by lax sealing. Therefore, in order to improve the tightness, some power plants install such cut-off valves in the direction of ' high inlet and low outlet '.