The Harm And Protection Of Abnormal Pressure Rise Of Gate Valve

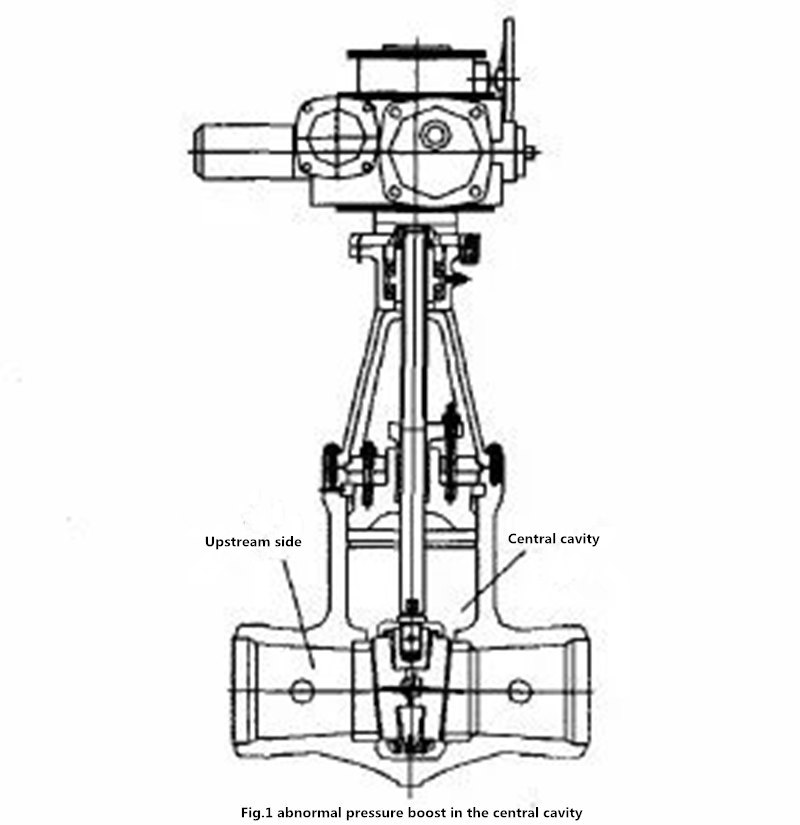

The gate valve usually has the structure design of single gate, double gate, wedge, parallel and so on. Among them, wedge double gate and wedge elastic gate are the most widely used. When the former is closed, the gate automatically coincides with both sides of the valve seat, and automatically compensates the machining position error of the wedge angle. The latter relies on the elastic groove in the middle of the gate and the axial thrust of the valve stem to compensate the machining position error of the wedge angle, both of which achieve better sealing effect. It is precisely because of its excellent sealing on both sides that the pressure in the middle cavity will increase abnormally in some occasions. When the high-temperature and high-pressure fluid ( liquid or gas ) is blocked in the middle cavity of the valve, if the temperature of the fluid on the upstream side increases, the fluid in the middle cavity ( see Fig.1 ) will be synchronously increased by heat transfer. Due to the inability of the middle cavity to expand, when the fluid in the blocked middle cavity changes from cold to hot, the liquid may vaporize rapidly, resulting in a sharp increase in pressure. The increased pressure is often a geometric series.

The consequences of valve overpressure work is very serious. When the valve cavity is abnormally boosted, the working stress of the pressure-bearing parts and the opening and closing parts ( such as the use stress of the valve stem and the gate frame ) will increase sharply, and the driving force of the driving mechanism will be overwhelmed, or even unable to start. In severe cases, the valve stem is broken, the gate frame is broken, and the motor is burned. These phenomena are common in many high-pressure large-diameter gate valves. Many users often complain that this is the gate ' bite '. In fact, the real reason for ' bite ' is often the ' invisible killer ' of abnormal pressure rise in the cavity.

In a typical case, when the wedge double gate valve is used in the water supply system of thermal power plant and its bypass, this kind of valve is generally closed after the cold water pressure test. When the system temperature rises to 250 ~ 300 °C when the unit is started, the cold water temperature in the closed middle will rise sharply and vaporize synchronously due to the sharp rise of temperature, which will increase the fluid volume and pressure. At this time, if the valve is opened, either the driving torque is large enough or the strength of the valve stem assembly is high enough. Otherwise, the valve stem fracture, gate frame fracture, gate T-groove flowering and fracture often occur, so that the feed water pump cannot be started, resulting in serious shutdown accident.

The harm of abnormal pressure rise

The formation of abnormal pressure rise will occur surprisingly similarly in many applications of gate valves, because the two major elements of its occurrence are similar in many industrial systems, that is, the system medium changes from cold state to hot state after starting up ; the gate is closed in cold state and opened in hot state. Therefore, if no measures are taken to the system, the damage to the system caused by abnormal boost is almost unavoidable, which has three hazards :

1.Damage to the valve itself

The strength of the valve shell, valve cover and valve stem parts is generally designed by the nominal pressure of the valve. When the abnormal pressure is raised, the opening pressure will be doubled, resulting in the use stress of the related parts to be doubled. When the actual stress of the material exceeds the allowable stress, the high stress part will be broken, resulting in the valve unable to open, and the valve will be damaged or scrapped.

2.Damage to system security

Obviously, the shell, valve cover and other pressure parts are very dangerous when overpressure occurs. Once the overpressure occurs, the weak parts may be perforated first, causing medium leakage ; the filler and self-sealing ring parts are often washed out by high-pressure fluid, causing a large amount of medium leakage. When the medium is a high temperature gas, toxic gas, harmful gas will be more serious, and even cause damage to equipment and personnel.

3.Cause huge losses to the production control process

The normal opening and closing of valves is the key to all kinds of industrial process control. Once this control cannot be realized, the system must be shut down for maintenance, which will cause huge direct or indirect losses.

Protective measures

Starting from the aspects of design, installation and debugging, it is entirely possible to fundamentally eliminate the abnormal boost of the middle cavity. Three commonly used schemes are summarized for the reference of the majority of users :

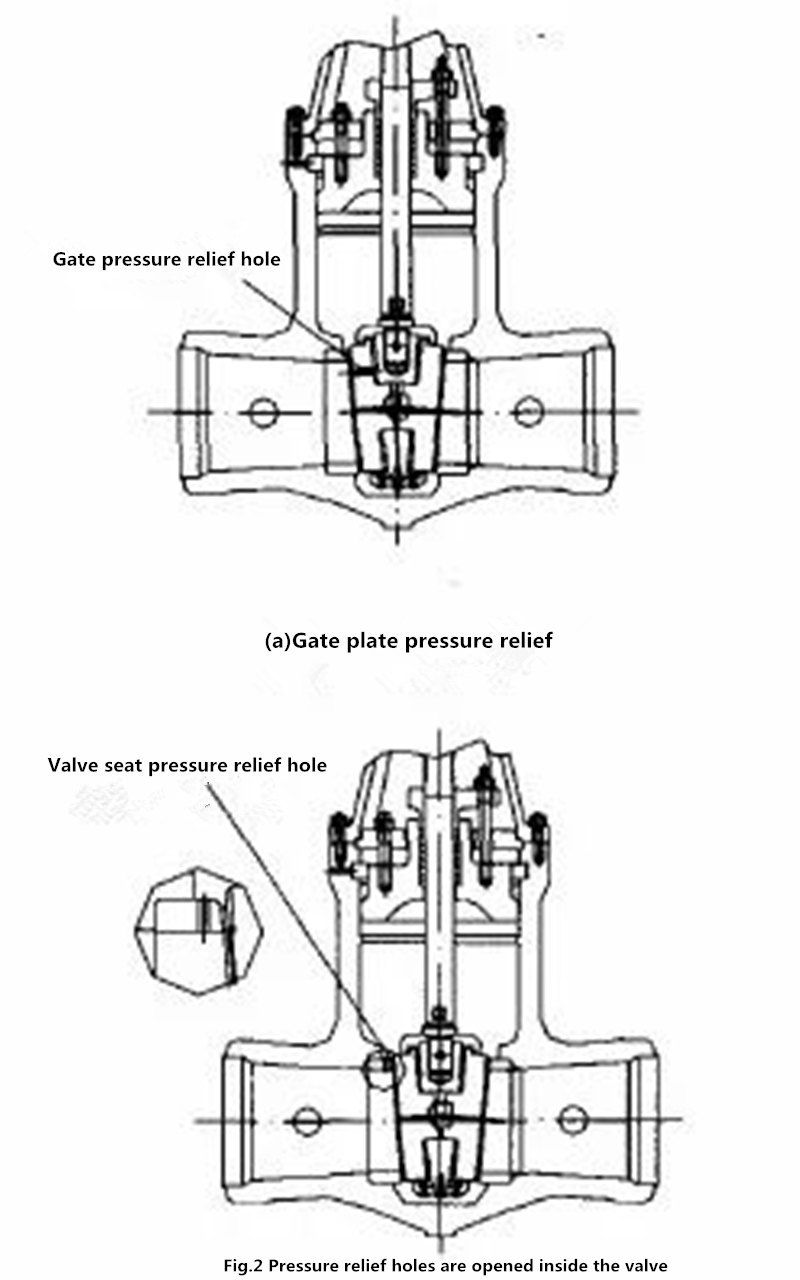

1.Opening pressure relief holes inside the valve

The fundamental solution to the abnormal pressure rise of the middle chamber is to balance the pressure of the middle chamber. Opening the pressure relief hole is the most economical and effective solution. As shown in Figure 2, the pressure relief holes are opened on the upstream side gate and the outer circle of the inlet side valve seat. When the pressure of the middle chamber increases, the pressure of the middle chamber will automatically discharge to the upstream side, and the pressure of the middle chamber will always be equal to the pressure of the upstream side, so as to avoid the occurrence of abnormal pressure rise.

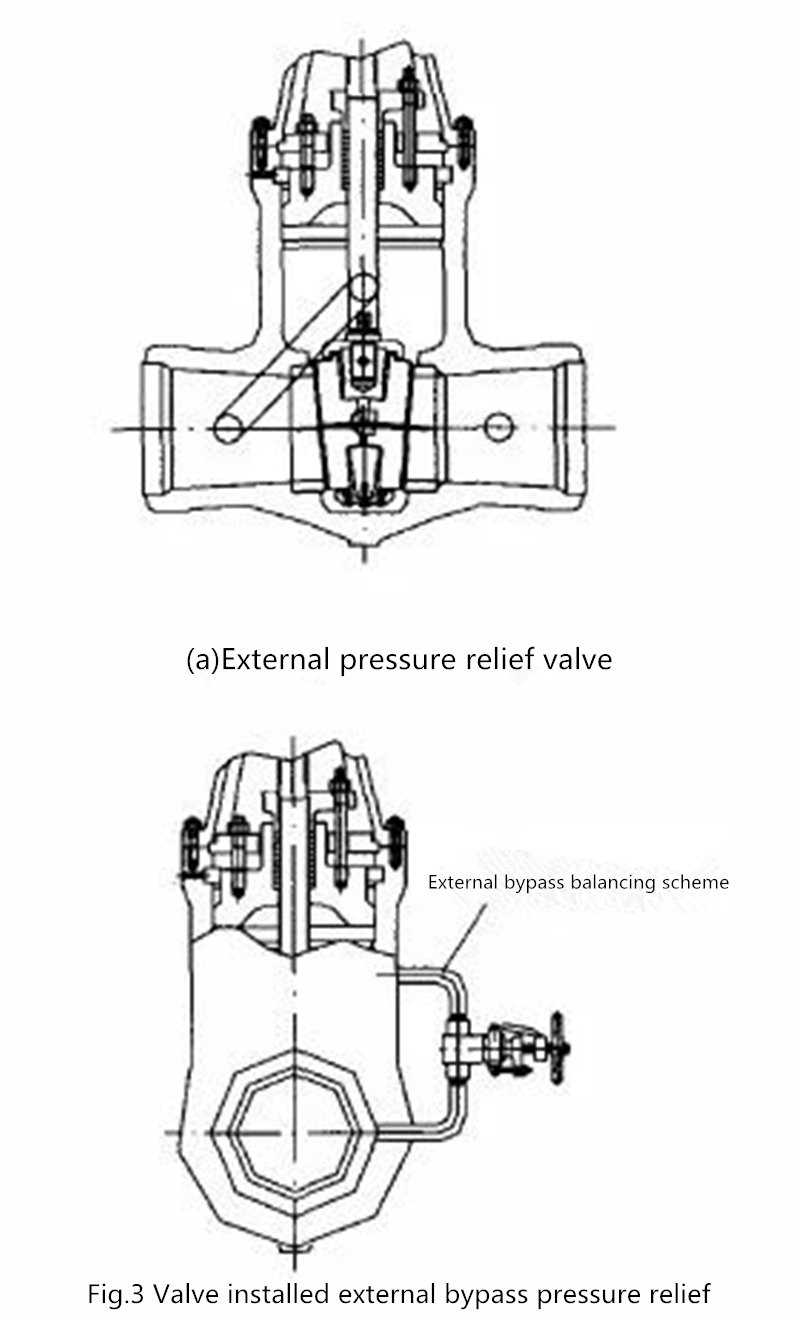

2.Valve installed external bypass pressure relief

For the manufactured valves, the external bypass and external pressure relief valve can be used to reduce the cavity pressure during installation, as shown in Figure 3.

The bypass with shut-off valve is used to connect the middle cavity and the upstream side. When the main gate is closed, the shut-off valve can be closed ( depending on the temperature change of the middle cavity, it must be opened when it is too high ). When the main gate valve is opened, the bypass stop valve should be opened first, and the main gate valve should be started after reducing the pressure of the middle chamber.

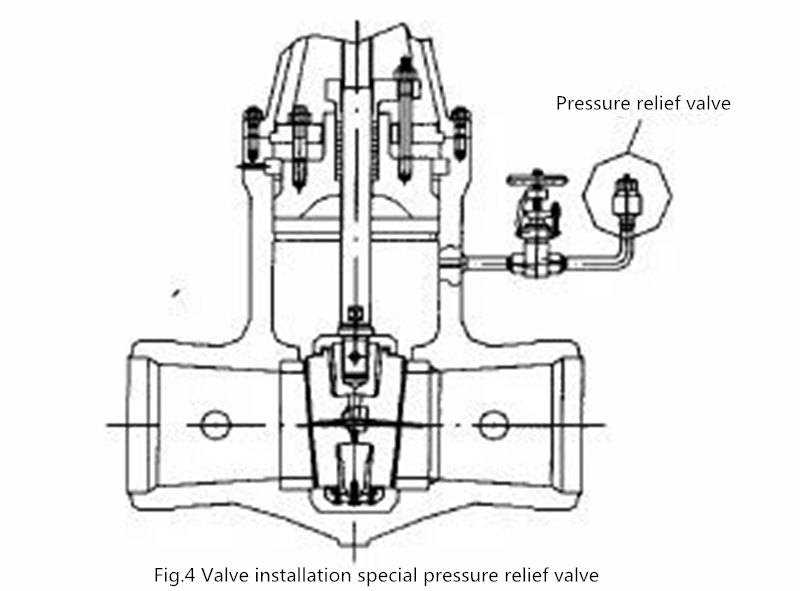

3.Special pressure relief valve is installed outside the valve

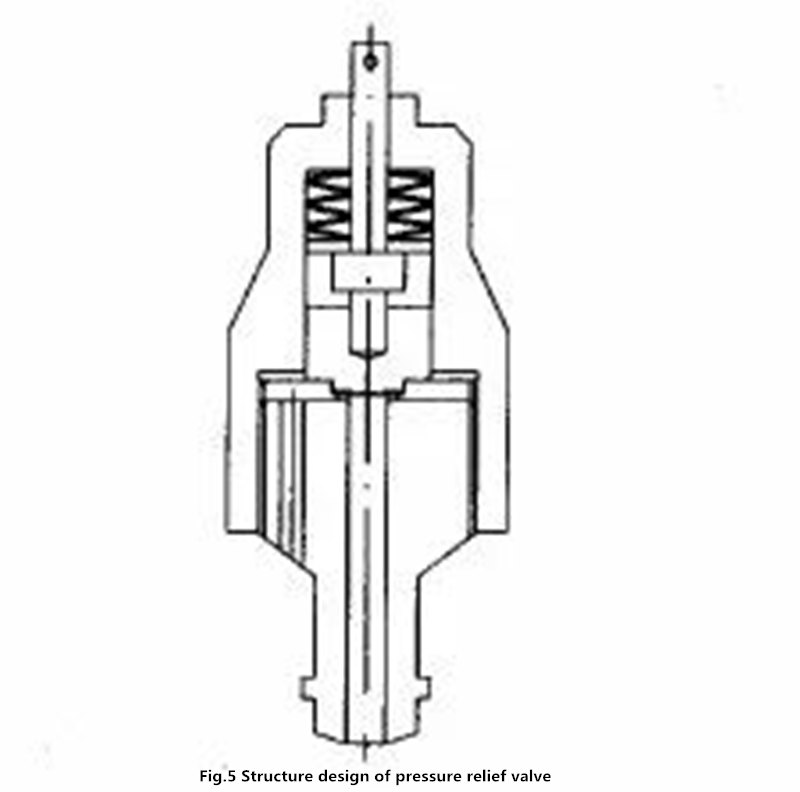

Fig.4 shows the control pressure range of the pressure relief valve set outside the middle chamber of the gate valve. The discharge pressure of the pressure relief valve is set as the rated working pressure of the main valve. When the middle chamber is overpressured, it is automatically discharged to the set pressure to maintain the safe operation of the main gate valve.

Figure 5 is the structural design of the relief valve ( for reference ). A stop valve is installed in front of the pressure relief valve to facilitate the adjustment and maintenance of the pressure relief valve. The pressure setting of the pressure relief valve can usually be considered as 1.33PN ( PN is the nominal stress of the system valve ).

In addition, when the valve is debugged, especially when the electric valve is debugged, attention should be paid to the control of the closing stroke and torque, and the closing torque should be reduced as much as possible to prevent the wedge dead gate ; the high temperature valve should consider the wedge death of the gate caused by the thermal expansion of the valve stem in the high temperature state. It is recommended that when the high temperature and high pressure large diameter gate valve is debugged, the stem should be properly retracted after the gate is in place to avoid the real bite accident.