BESTOP Brand Big Size Rubber Expansion Joints Produced By Hand Winding Are Shipped

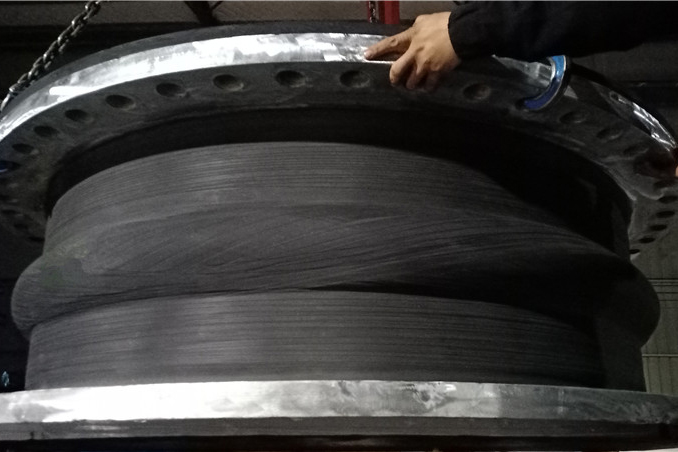

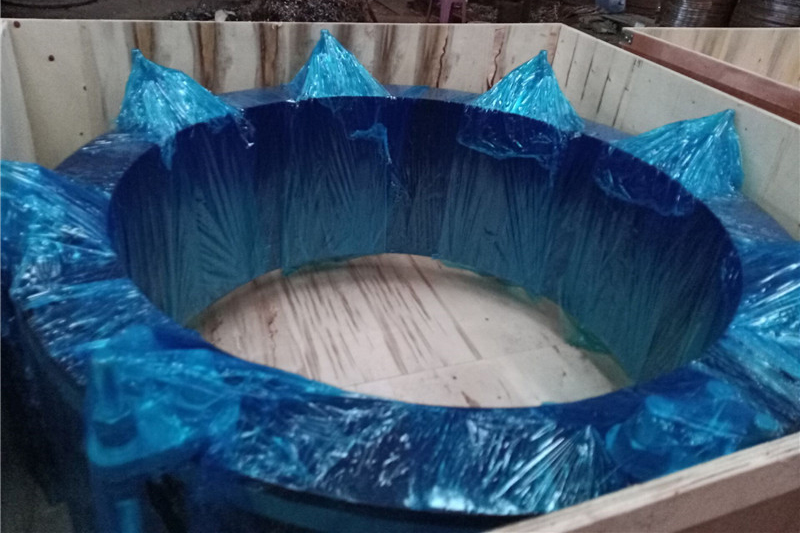

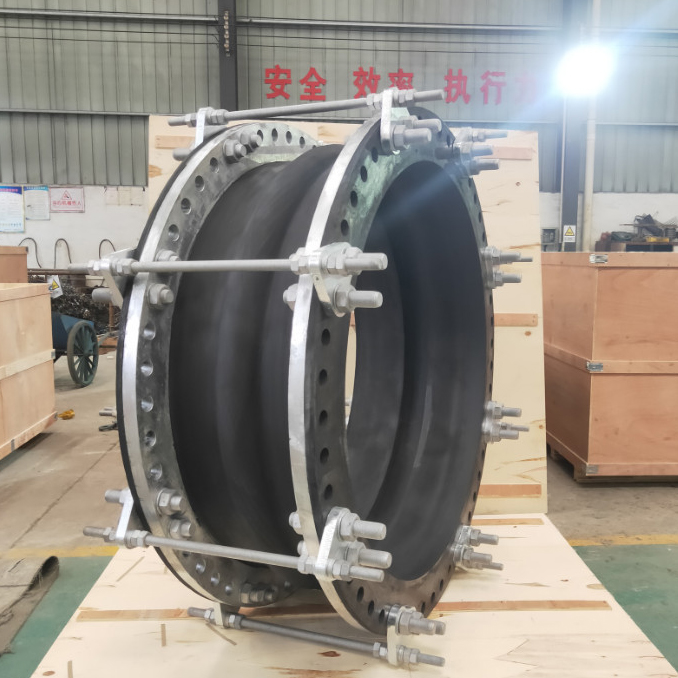

32pcs DN1300 and 24 PCS DN1500 rubber expansion joints are finished hydraulic testing today and will be packed for shipment. These rubber expansion joints are for a power station project in Israel. The customer requested hand winding . For such big size rubber expansion joint , it is really difficult to make by hand winding . The technical procedure is complicated and meticulous. During production, the winding of rubber layer and curtain needs to follow certain rules and skilled techniques. All handmade All hand made when winding. Before wind the first wire , by direction , the wire will pass through the wire loop, tension installation , line sheets,shaping outlet, and then pressed tightly with tape on tube of the tractor according to the the wingding direction. And then starting winding machine, the tube was slowly forward, through the governor, adjusting the tracking speed with the governor in order to make winding trip up to par, Such winding will be turn and turn about. It needs the workers must be skilled.

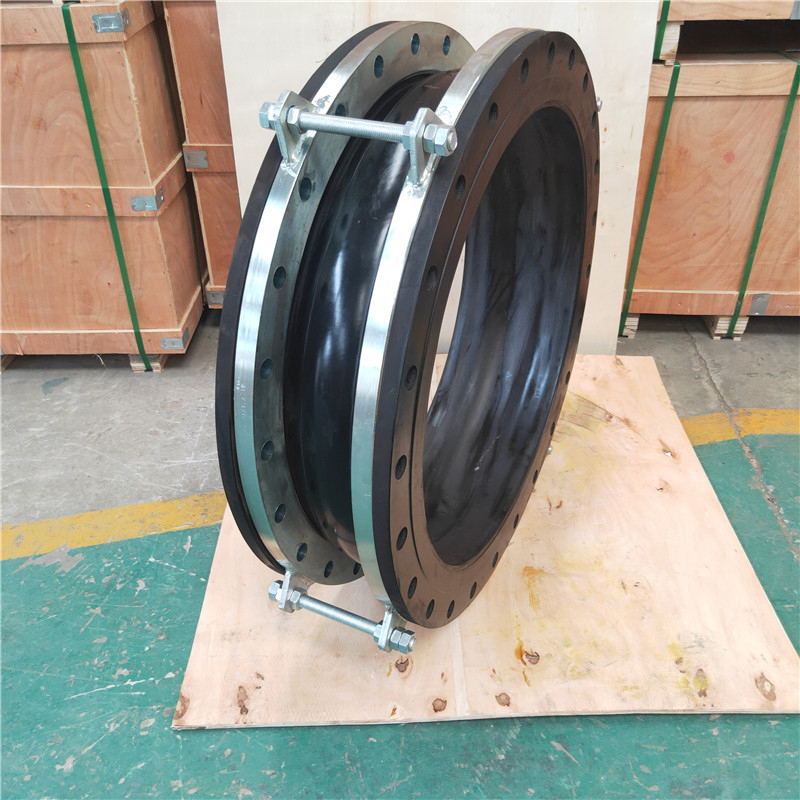

Our technicians and engineer tired again and again , at last they succeed to meet the customers’ requirements. Hand winding rubber expansion joints have more better advantages in application than the normal ones:

1.It can reduce the vibration and noise more better ;

2.It has more bigger offset compensatory to the pipeline.

3.Its performance of pressure resistance is much better .In the case of negative pressure working conditions, stainless steel wire of negative pressure resistance can be added in the production process or the inner wall is made into straight cylinder type, in order to achieve the application condition.

4.Hand winding rubber expansion joint is of much longer service life;

The hand winding rubber expansion joint has very excellent performance in corrosion resistance, excellent oil resistance, heat resistance and aging resistance, which can be used in pipeline of flue gas desulfurization.