Several Differences Of Valve Flange, Socket Welding And Butt Welding

1.Flat welding, butt welding and socket welding flange

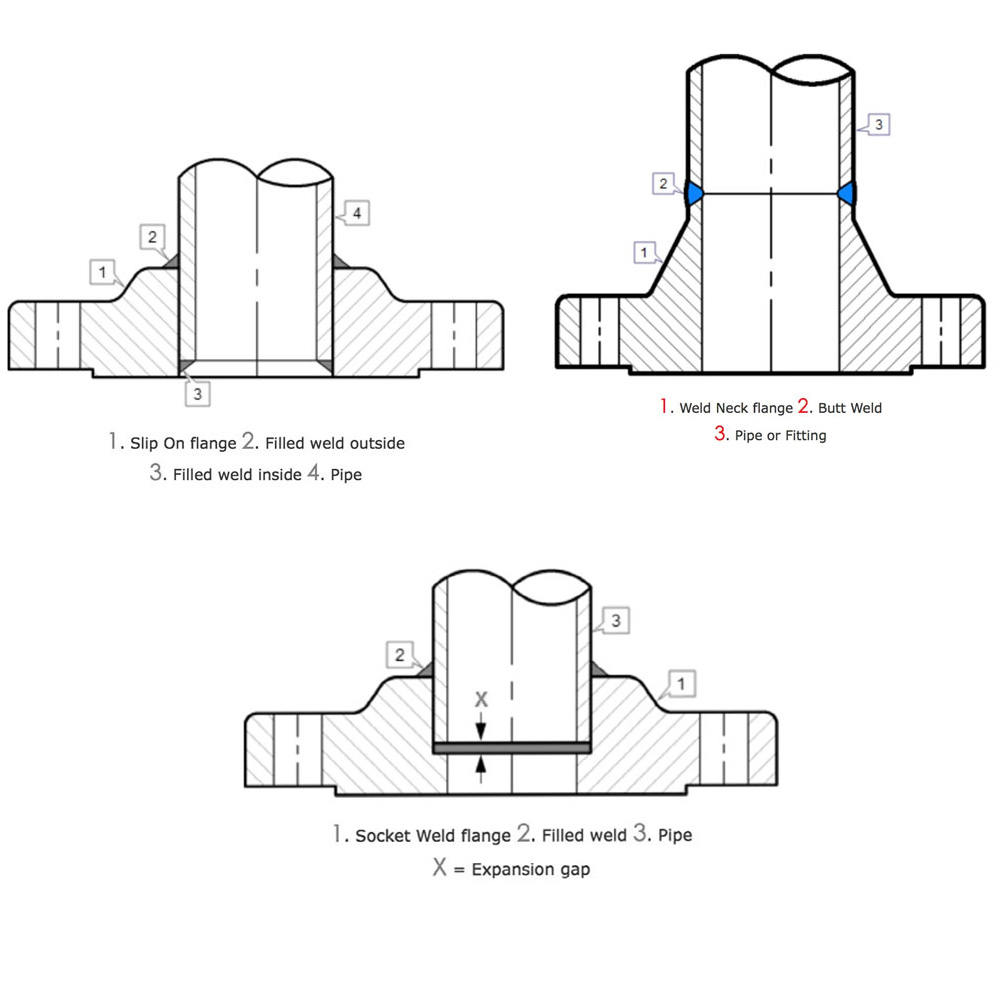

Pipe flange welding has the form of flat welding, butt welding and socket welding flange

Socket welding generally inserts the pipe into the flange for welding. Butt welding is to butt weld the pipe and butt surface with butt welding flange,Ray detection cannot be performed on the socket weld, but butt welding can be done.Therefore, it is recommended to use butt welding flange for high welding detection requirements.

2. Several differences and applications

Generally, the requirements of butt welding are higher than those of socket welding, and the quality after welding is also good, but the detection means are relatively strict. Welding to do ray flaw detection, socket welding do magnetic powder or penetration testing can be ( like carbon steel do magnetic powder, stainless steel do penetration ). If the fluid in the pipeline does not require high welding, it is recommended to use socket welding for convenient detection.

Most of the connection forms of socket welding are used in small diameter valves and pipelines, pipe fittings and pipeline welding. Small-diameter pipes are generally thin in wall thickness, easy to be misaligned and ablated, and difficult to weld, so they are more suitable for socket welding. In addition, the socket of socket welding has a reinforcing effect, so it is also used under high pressure. However, socket welding also has disadvantages. One is that the stress condition after welding is not good, and it is easy to cause incomplete penetration of welding. There are gaps in the pipe system. Therefore, socket welding is not suitable for the pipe system used for crevice corrosion sensitive medium and the pipe system with high cleanliness requirements. Furthermore, ultra-high pressure pipelines, even if the wall thickness of small-diameter pipelines is also large, can be butt welded connection as far as possible to avoid socket welding.

In short, socket welding forms fillet weld, while butt welding forms butt weld. From the analysis of the strength and stress state of the weld, the butt joint is better than the socket joint, so the butt joint should be used in the case of high pressure level and poor service condition.

3. Flange selection

1.According to the material of the pipeline to choose the real suitable flange material, such as stainless steel pipeline is certainly not allowed to choose carbon steel flange ;

2.According to the nominal diameter ( DN ) of the pipeline and the nominal pressure ( PN ) of the whole pipeline system, the right flange is selected. At present, the international pipe flange basically adopts the American standard system and the European standard system ;

3.According to the specific working conditions, the flange structure and form are selected : such as flat welding with neck, loop flange, etc., and the sealing surface has a protruding surface, a full plane, a concave and convex surface, etc.

For non-standard parts, it is necessary to design and manufacture according to the flange specification design procedure.