Safe Operation Of Valves And Centrifugal Pumps

The pump is the core device of the fluid industry. It acts like the heart of the human body, providing power for the fluid in each device in the system and ensuring the normal operation of the process. Commonly used pumps are classified into vane pumps, positive displacement pumps, special purpose pumps, etc. Among them, centrifugal pump in vane pump is the most widely used.

Two problems need to be avoided during the operation of centrifugal pump: stop the pump hammer and less than the minimum flow. There are many ways to solve these two problems, but the basic idea is how to configure a suitable system around the centrifugal pump. Valves play a very important role in these systems, and with the deepening understanding of these two types of problems, many special valves have been born.

First, stop the pump water hammer protection and valve

Water hammer is a series of water hammer phenomena caused by the drastic change of medium velocity in pressure pipeline. Water hammers can be very harmful and can destroy pumps, lines and other equipment. There are many reasons for the water hammer in the pressure pipeline, such as the rapid closing of the valve, abnormal stop of the pump and so on.

Production mechanism of water hammer when the pump stops

When for abnormal reasons, such as power failure, the pump suddenly stops working : in the initial stage, the medium in the pipeline continues to move forward by inertia, but the speed is gradually reduced to zero ; at this time, if there is a height drop in the pipeline layout, the medium will flow backward to the pump under the action of gravity ; when the backflow medium reaches a certain speed, the check valve at the outlet of the pump will be quickly closed. In this way, the speed of a large amount of medium reaching here suddenly becomes zero, causing a sharp increase in the pressure of the medium here-stop water hammer. A large number of literatures have pointed out that the main cause of the water hammer is the sudden closing of the check valve at the outlet of the pump. However, studies have shown that although the check valve at the pump outlet can be cancelled in some cases, in most cases, the anti-backflow setting at the pump outlet is necessary to prevent a large amount of medium from backflowing into the centrifugal pump.

Measures to avoid water hammer caused by stopping pump

There are many measures to avoid the harm of water hammer when the pump stops, such as the installation of water hammer eliminator, pressure relief valve, pressure regulator, etc. The following only introduces two widely used measures related to general valves.

1. Set the slow closing check valve

Slow closing check valve is a kind of slow closing check valve by adding actuator, damper. The figure above is the schematic diagram of the centrifugal pump stop pump water hammer protection system installed with the slow closing check valve. At this time, the slow closing check valve needs to be used with the gate valve (switch valve). When the medium backflows under gravity, the check valve closes slowly, effectively avoiding the water hammer caused by the sudden closing of the ordinary check valve. Its disadvantage is that because the closing speed is slow, part of the medium will inevitably flow back into the centrifugal pump, so the pump may produce mechanical failure.

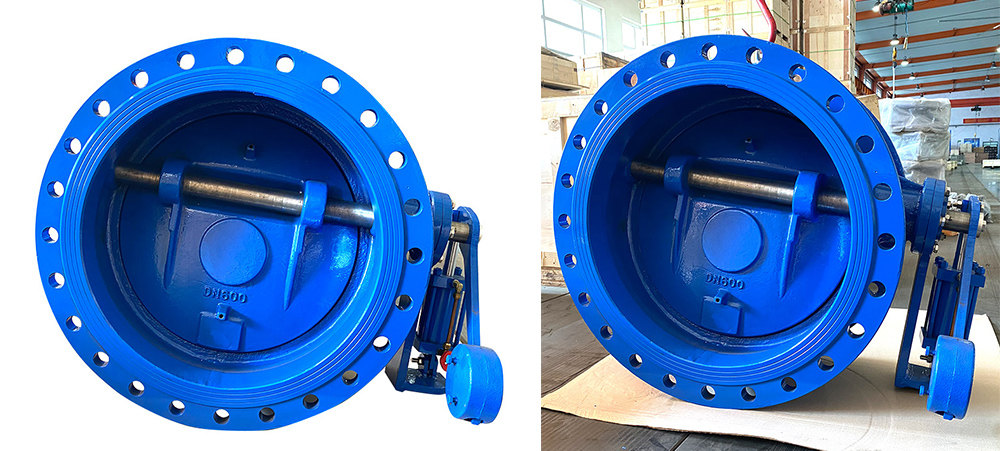

2. Set the slow closing check butterfly valve

This is a common and effective method used in large water conservancy system. Slow closing and non-return butterfly valve is composed of butterfly valve, executive structure and hydraulic control system. The figure above is a schematic diagram of the centrifugal pump stop pump water hammer protection system with slow closing and non-return butterfly valve. The system only needs to install the slow closing check butterfly valve, which can play the role of check valve and switch valve. When the centrifugal pump is opened, it is opened by the first slow and then fast steps to ensure that the pump is open with low load; When the pump suddenly stops working, it is closed by the first fast and then slow steps, which can avoid the production of water hammer, and can avoid too much media backflow through the pump, causing mechanical failure of the pump.

Avoid minimum flow conditions and valves

The minimum flow refers to the flow that ensures the normal operation of the pump. If the pump works below the minimum flow rate, it will cause noise and vibration, the performance of the pump will become unstable, and even cause abnormal cavitation of the pump, reducing the service life of the pump. Therefore, measures must be taken to avoid the centrifugal pump working under the minimum flow condition. At present, the common practice is to feed the centrifugal pump to set the minimum flow circuit. However, in terms of the value of the pump itself, it is only reasonable to set the minimum flow circuit for centrifugal pumps with large flow, high lift and high power. The minimum allowable flow value of the centrifugal pump is determined by the pump manufacturer 's calculation or experiment.

The simplest minimum flow circuit only needs to install a switching valve in the circuit, such as a gate valve. When the pump is considered to be about to be in the minimum flow condition, the valve is opened and the minimum flow circuit is connected to avoid the pump working under the minimum flow condition.

3. Summary

The basic structure of the valve introduced above is the same as the general valve, but because of the corresponding improvement according to the application conditions, these valves become special valves to solve these two problems.